|

|

|

|

|

Polyphase

induction motor with solid-iron slotless rotor offers undoubted

advantages in terms of construction simplicity and strength over

conventional induction motors, even though its efficiency is much

lower. This solid-rotor motor is especially suited for applications

that require frequent starts.

Several Authors have

studied this solid-rotor induction machine using analytical methods

for a two-dimensional representation, by using either cylindrical or

Cartesian co-ordinate systems. The studies have been generally

restricted to the sinusoidal steady-state operation, even if an

analysis in terms of the two-reaction theory has been developed. The

major difficulty for a satisfactory analysis of the solid rotor

machine derives from the necessity to take saturation into account. In

fact, owing to the relatively small skin-depth, the rotor is usually

highly saturated. In the literature saturation effects are either

neglected or else procedures based on the choice of a trial and error

value for the average iron reluctivity are adopted. In the latter case

reference is usually made to the BI-H curve. This curve relates the

fundamental amplitude of

B to the

amplitude of H (which is assumed to be sinusoidal) and is derived from

the normal magnetisation characteristic B-H.

The finite element method,

on the other hand, allows the reluctivity of each individual iron

element to be evaluated. If the distortion introduced by the odd

harmonic components of magnetizing current is ignored, the sinusoidal

steady-state operation may be studied by the use of complex numbers.

If this is not done it becomes necessary to solve a time dependent

problem.

In this research, the

three-phase induction motor with smooth solid-rotor has been studied

by a two-dimensional finite element analysis. A machine with this kind

of rotor is particularly suitable for investigation by the finite

element method, since the machine geometry (as observed in a reference

frame on the stator) does not vary with the rotor motion.

Features of the study:

Ø Complete

representation of the magnetic behaviour of the iron in the machine

Ø Analysis

of the machine as a whole

Ø Determination

of the magnetic field for a given system of supply voltages.

Ø Prediction

of the performance under voltage-forced operation.

Ø Calculation

of every steady-state operating point as the asymptotic solution of

the electromagnetic field partial differential equation for a fixed

constant speed and for a given symmetric system of sinusoidal supply

voltages.

Ø Comparison

of the calculated electrical and mechanical quantities with

experimental results. |

|

|

|

|

|

|

|

The

linear actuators are increasingly employed as direct actuators in

servo systems replacing the more conventional mechanical systems.

The use of permanent magnets on the slider offers several advantages

associated with the absence of electrical connections and heating

effects due to copper losses. In addition, the use of a slotless

armature results in a simplified construction. The design of these

linear actuators is optimised for maximum force to total mass ratio

and for maximum force to moving mass ratio. In order to analyse the

dynamic behaviour a mathematical model based on a simplified field

analysis is developed. Numerical simulations of the step response of

a positioning servo system are now under investigation.

|

|

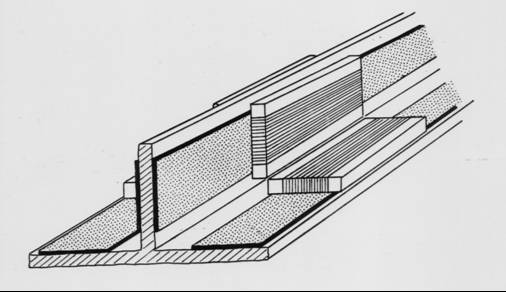

Fig. 1- Schematic drawing of the PM DC linear actuator.

|

According to these

considerations a very simple and low cost PM DC linear actuator is

investigated which consists of a slotless armature and a permanent

magnet slider, as represented in Fig. 1.

It has been verified

that the magnetic circuit geometry allows the magnet to operate at

low demagnetising field if the Ampere-turns of the armature

winding are compensated. For this purpose, in addition to the

winding distributed over the working length, two coils are placed

at the ends of the actuator. The compensation of the armature

Ampere-turns is very important to achieve high thrust values. The

compensating coils can be replaced by distributed windings leading

to geometries which can drive two sliders. |

|

|

Simple linear models are not suitable to predict the performance of

the linear actuator shown in Fig. 1 as the stroke length is much

larger than the magnet length and the winding current is increased

beyond the rated value. Numerical techniques such as the

finite-element method can be used to determine accurately the actuator

performance, taking the non-linear behaviour of the iron circuit and

magnet material into account.

Plot of the flux density distribution |

|

|

|

Main Contribution |

|

|

|

Ø Two-dimensional

Finite Element field analysis

Ø Determination

of the effects of the iron core saturation on the thrust versus slider

position curve

Ø Calculation

of the peak force during temporary overload conditions

Ø Calculation

of the transformer and dynamic coefficients of the machine

Ø Definition

of the dynamic model of the linear actuator

Ø Compensating

coils replaced by distributed windings leading to geometries which can

drive two sliders

Ø Comparative

analysis |

|

|

MAGNETIC LEVITATION SYSTEMS

FOR HIGH SPEED GROUND TRANSPORTATION

|

|

|

|

The

research concerns the analysis of the vertical dynamics of an

electrodynamic levitation system using superconducting coils and a

passive and/or damping system.

In high speed magnetically

levitated vehicles the levitation systems based on repulsive forces

are statically stable but dynamically have zero or low damping

characteristics. In order to damp the vertical oscillations, passive

damping systems, constituted by short circuited coils placed under the

levitation coil, can be used. However, passive damping systems

usually do not provide the required ride quality. Then, the damping

effect on the mechanical oscillation of the vehicle should be

improved by using an additional active damping system.

The performance of combined

active and passive damping system has been evaluated. The active

damping has been performed by a coil current control using mechanical

or electrical transducers. It has been observed that, in general, the

control system based on mechanical transducers performs better than

that based on electrical transducers.

|

In the research, the

analysis of a control system for active damping which does not

require vertical position, velocity or acceleration measurement is

presented. The control system operation is based on sensing the

current in the damping coil and regulating the supply voltage

according to a suitable control law. The stability analysis has

been performed. |

Fig. 1 - Schematic cross-section of the levitation system

with damping coils. |

|

|

The effectiveness of the levitation

system is verified by calculating the response to a step track

disturbance and analysing the Power Spectral Density (PSD) of the

vertical acceleration due to a random track disturbance.

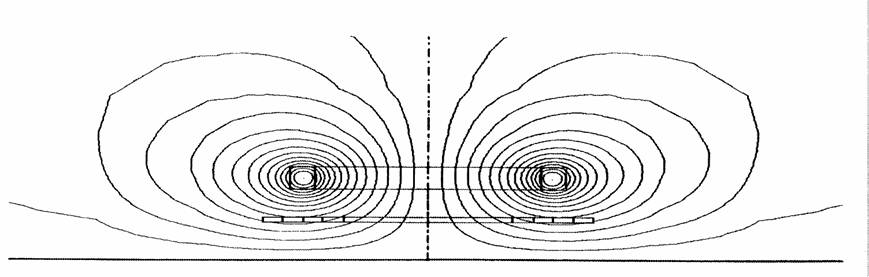

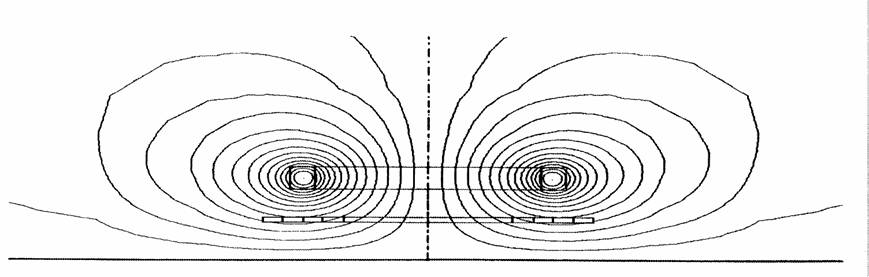

Fig. 2 shows a plot of the

flux distribution due to the superconducting coil current assuming the

conducting sheet to behave as a perfect diamagnetic material for high

values of the vehicle speed. |

|

Fig. 2 - Plot of the flux distribution due to the superconducting

coil,

z = 0.25 m, d=0.10 m. |

Fig. 3 - Vertical acceleration PSD for A=1.25 10-6 m

and v = 100 m/s. |

|

|

Main contributions |

|

|

|

Ø Performance

evaluation of combined active and passive damping

Ø Active

damping performed by a coil current control using mechanical or

electrical transducers

Ø Analysis

of a control system for active damping which does not require vertical

position, velocity or acceleration measurement

Ø Control

system operation based on sensing the current in the damping coil and

regulating the supply voltage according to a suitable control law

Ø Stability

analysis

Ø Evaluation

of the effectiveness of the levitation system by analysing the Power

Spectral Density (PSD) of the vertical acceleration . |

|

|

PERMANENT MAGNET ACTUATORS:

REDUCTION OF THE TORQUE RIPPLE BY A MULTI-OBJECTIVE MINIMIZATION

TECHNIQUE

|

|

|

|

The demand for high performance

Permanent Magnet (PM) motors is continuously increasing in industrial

applications because of their high efficiency and power density. The

machine inherently has a torque ripple which causes vibrations and noises.

This deteriorates the performance of position control systems and speed

control systems at low speed. As a consequence, it is important to find

out methods for reducing the torque ripple to acceptable values.

With reference to sinusoidal PM

machines with surface-mounted magnets, there are mainly two contributions

to the torque ripple. The first one is the cogging torque which arises

from the interaction of the magnets with the stator teeth. As a result,

the torque is generated by the tendency of the rotor to align with the

stator at positions where the permeance of the magnetic circuit is

maximized. The second contribution is the torque ripple caused by the

presence of harmonics in the air-gap flux density distribution of the

magnets, which leads to non-sinusoidal components of the Electromotive

Force (EMF).

Many studies concerning the

analysis of the cogging torque have been carried out. The most effective

solutions proposed for the cogging torque reduction are the adjustment of

the magnet arc width relative to the slot pitch, the shifting of the pole

pairs and the skewing of either the stator slots or the rotor magnets.

Other methods which have been proposed for reducing the cogging torque

include the presence of dummy slots or dummy teeth in the stator

laminations, and the shaping of rotor magnets.

The influence of field

harmonics on the induced EMF may also be reduced acting on the stator

winding distribution or adopting a fractional number of slots per pole.

The skewing of stator slots and rotor magnets can also be used to reduce

the harmonic content of the induced EMF. However, the impact of all these

techniques cannot be considered separately for the two contributions to

the total torque ripple. A tight relationship between the two

contributions exists. The solutions employed to reduce the cogging torque

also affect the torque ripple produced by the harmonic content of the

induced EMF. As a consequence, the problem of the torque ripple reduction

should be considered on the whole and in most cases a compromise has to be

made to minimize the total torque ripple.

In the research, the

minimization of the torque ripple is formulated as an optimization design

problem, without separating the different contributions. In order to do

this a two-step design procedure has been proposed. In the first step a

global minimization algorithm coupled to a one-dimensional field analysis

is utilized. The minimization technique is based on the Evolution Strategy

(ES) method. The minimization algorithm proposed considers the enhancement

of the fundamental component of the induced EMF and the minimization of

the two torque ripple contributions. A multi-objective problem is stated

and solved by means of a penalty technique.

Once the design unknowns have

been determined by the proposed procedure, the magnet arc width has been

further optimized to minimize the cogging torque. For this purpose a

two-dimensional Finite Element (FE) analysis has been used to determine

the flux density distribution of the magnets. |

|

Fig. 1 - Plot of the rotor geometry (solution

A). |

Fig. 2 - Plot of the magnetic field

(solution A) |

|

Fig. 3

- Schematic drawing of the magnet skewing. |

Fig. 4

- Prototype realized on the basis of the results

obtained for Solution B. |

|

|

The example presented

considers a 3-phase, 6-pole PM synchronous machine with sinusoidal EMF

and magnets placed on the rotor surface. Since the stator skewing

increases the complexity of machine construction, a skewed mounting of

discrete magnet segments on the rotor has been considered.Two

different magnet arrangements have been investigated. In the first

one, the sum of the magnets’ width is smaller than the rotor periphery

length. In the second one, the sum of the magnets width is equal to

the rotor periphery length. Therefore, the rotor surface is completely

covered by the PMs. This configuration allows the realization of the

magnetic part of the rotor using a tube of a polymer bonded magnetic

material and simplifies the manufacturing of the motor, since the

magnet material can be directly molded onto the rotor eliminating

subsequent assembly steps. In this work, the analysis will be mainly

focused on the second magnet arrangement type.

Experimental tests of the machine constructed by

means of the design procedure described, have been done. The test

results meet the design requirements.

|

Fig. 5

- Cogging torque

Fig. 6 - Cogging torque curves for Solution B. |

|

|

|

|

MAIN CONTRIBUTIONS |

|

|

|

Ø

Minimization of

the torque ripple, formulated as an optimization design problem

Ø

Minimization of

the torque ripple without separating the different contributions

Ø

Definition of a

two-step design procedure

Ø

Minimization

technique based on the Evolution Strategy (ES) method.

Ø

Multi-objective

problem solved by means of a penalty technique

Ø

Optimization of

the magnet arc width in order to minimize the cogging torque

Ø

Use of a

two-dimensional Finite Element analysis to determine the flux density

distribution of the magnets. |

|

|